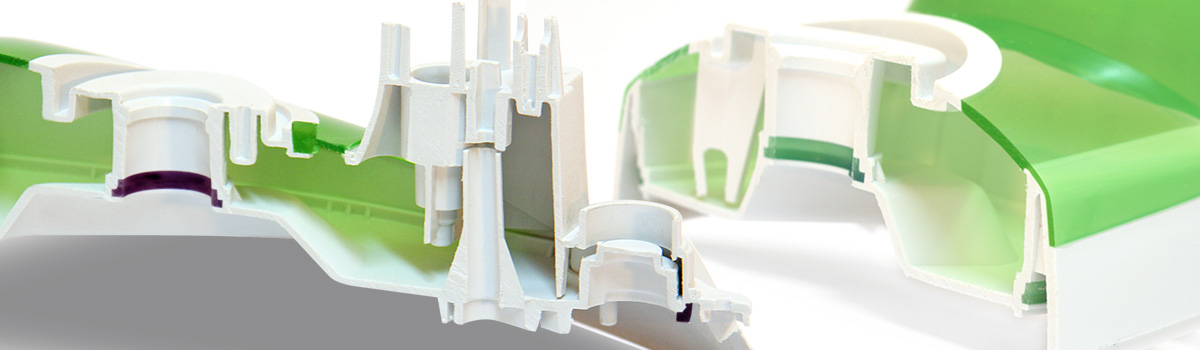

One of the most critical factors of success in a turn-key project is the development of the best mould concept. Plasdan has a very experienced mould engineering team that assures the successful completion of such an important goal. Our Engineering team will focus on the definition of the desired/required performances. They can also assist in redesign/reengineering of the product to better suit the chosen process with enhanced performance. This task is carried out, also taking into consideration costs, reliability and Industrialization.

We focus on defining customer needs and required functionality early in the development cycle, documenting requirements, then proceeding with design and system validation while considering costs, timing, performance, manufacturing and maintenance. We aim to integrate all the disciplines and speciality groups into our team effort, forming a structured development process that proceeds from concept to production, considering both the business and the technical needs of all customers with the goal of providing a quality product that meets the user needs.

Our team manager will plan, organize, secure and manage resources to achieve a successful project, bringing added value to the project. During the whole process, you will have a sole contact person responsible for the project management, saving time and increasing the project success. A team manager with an overview of the whole will spot eventual difficulties at an earlier stage. Good project management will achieve the required project goals and objectives within the agreed time schedule, budget and quality requirements.